These state-of-the-art cryomodules are equipped with superconducting Radio Frequency Dipole (RFD) crab cavities. The first cryomodule, will serve as a pre-series version for testing and validation of the RFD crab cavities at CERN, before the delivery of a series containing four more cryomodules.

Built at Daresbury Laboratory, the series of cryomodules will be installed on the Large Hadron Collider (LHC) as part of the High Luminosity Large Hadron Collider (HL-LHC) upgrade during Long Shutdown 3 during 2025 to 2027. The series delivered by the Science and Technology Facilities Council (STFC) will join with four others provided by colleagues at the Canadian particle accelerator centre TRIUMF.

Accelerating new discoveries

Straddling the Franco-Swiss border and located 100 metres below ground, the LHC at CERN is the world’s largest particle accelerator. Over the last 13 years, it has opened a new frontier of discovery in fundamental particle physics by colliding beams of protons at incredibly high energies. This has provided data for over 13,000 scientists worldwide.

The HL-LHC project aims to elevate the performance of the LHC. The objective will be to increase the number of particle collisions (integrated luminosity) by a factor of 10.

The development of crab cavities

To help increase the luminosity, crab cavities will be installed during the HL-LHC upgrade. What makes crab cavities special is the ability to ‘tilt’ the proton bunches. Particles already travel around the LHC in bunches, but these bunches have gaps between them. The HL-LHC upgrade will put more protons in the bunches and reduce the gaps between these bunches. This maximises their potential for head-on collisions in the LHC beams.

Two different cavity types have been developed for the upgrade. The first being the RFD and the second being the Double Quarter Wave (DQW). These two cavity types have been designed, developed and produced through a collaboration between STFC, Old Dominion University, Brookhaven National Laboratory and CERN.

Operating at -271.15°C (two degrees above absolute zero), these cavities are housed in state-of-the-art cryomodules. Keeping them at such cold temperatures ensures the correct operational environment is correct. This allows for precise alignment, mechanical support, cryogenic cooling, thermal and magnetic shielding, tuning capability, vacuum isolation, radio frequency power, monitoring of key parameters and all other connections to the outside world.

Continuous improvements

Colleagues at Daresbury Laboratory have been major partners in the project since 2011, initially working on earlier cavity and prototype cryomodule designs. These key contributions led to STFC being awarded the contract to assemble the pre-series RFD and a further four DQW cryomodules.

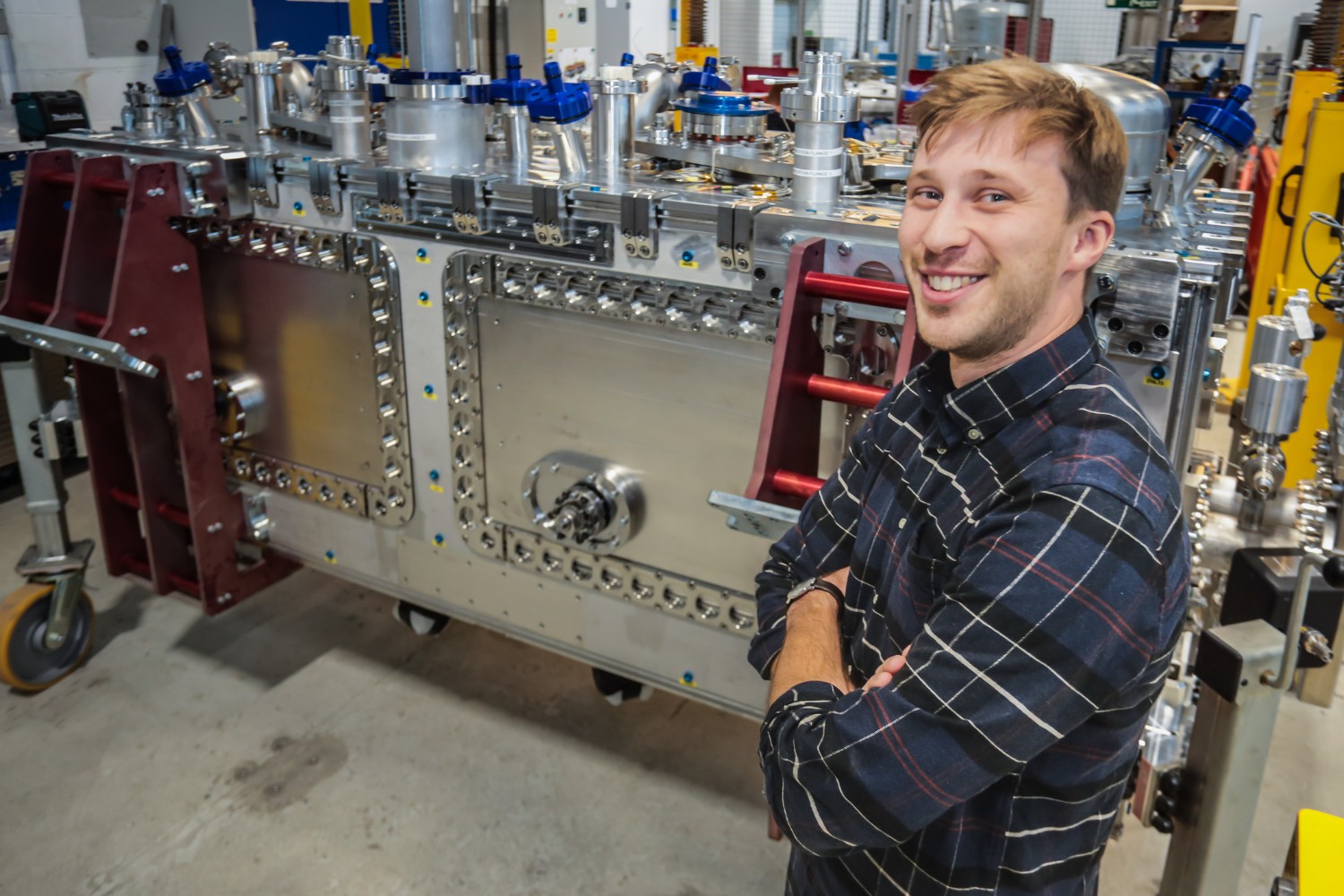

Niklas Templeton, Work Package Lead for the UK LHC Crab Cavity Cryomodules and Senior Project and Mechanical Engineer in STFC’s Technology Department said:

The state-of-the-art cryomodule is the first of its kind and a huge coup for the UK team to have built. After making several design contributions to the cryomodule including the thermal screen and cold and warm magnetic shields, the engineering team developed and delivered a suite of assembly infrastructure and tooling for the build.

Nik continued:

The team also delivered over 900 pages of detailed procedures which form the build quality assurance. Every step from cleanroom assembly to welding, cryostating and testing had to be developed and approved before execution. The team overcame many challenges which developed and demonstrated their multi-disciplinary skillsets and commitment. Truly great work!

The teams who worked on the technology. Credit: STFC Daresbury Laboratory

Bespoke infrastructure and upskilling

The cryomodule has taken almost two years of assembly work at Daresbury and contains around 10,000 components, of which more than 5,000 are unique. The team of STFC and Lancaster University experts have built upon existing expertise in areas such as mechanical and radio-frequency engineering, welding and project management.

This project has also supported significant upskilling of staff, with support from CERN, and the building of substantial new infrastructure for cryomodule assembly at Daresbury. This infrastructure includes custom test rigs, precision lifting equipment, and an ISO4 cleanroom for the assembly of the superconducting cavity string.

A global collaboration

The design, build and delivery of the cryomodule has been a global collaboration, with teams from both STFC and wider external partners working together to deliver new technology. This includes:

- RFD crab cavities – designed by Old Dominion University, manufactured, and qualified by CERN

- cryomodule – designed by CERN and STFC

- beamline components – supplied by CERN

- cryomodule components – delivered by CERN and STFC

- cryomodule outer vacuum chamber – delivered by Lancaster University

Next steps

The team at Daresbury bid farewell to the cryomodule on 18 October 2023, where it then undertook a three-day journey to CERN. To ensure safe transportation to CERN, STFC developed a custom anti-shock transport frame. Before the cryomodule embarked on its journey, the frame was successfully drop-tested with a dummy cryomodule, with results showing up to 80% damping.

This cryomodule will go through rigorous testing at CERN, including tests in the Super Proton Synchrotron, CERN’s second largest particle accelerator. The testing programme will provide key validation data for the RFD cavities ahead of the installation of the series cryomodules in LHC.

Dr Andrew Blackett-May, Project Manager for the cryomodule build and Senior Cryogenics Engineer in STFC’s Accelerator Science and Technology Centre said:

I’m incredibly proud of what the team have accomplished over the last two years. We have faced technical and logistical challenges getting to the point of successfully delivering the RFD cryomodule to CERN and huge credit is due to everyone involved for working so effectively as a team and delivering their work to such a consistently high standard.

This is a fantastic achievement for us at Daresbury Laboratory, as well as for UKRI-STFC and UK science and engineering more widely. We’ll be continuing to work very closely with our colleagues at CERN as they undertake the SM18 and SPS tests, and we look forward to sharing further news from these over the coming months.

Dr Andrew Blackett-May. Credit: STFC Daresbury Laboratory

Following the successful delivery of the pre-series module, teams across Daresbury Laboratory have already begun preparations for the building of four series modules beginning in 2024.